By Ken Robinson

FireRescue1 Staff

FORT COLLINS, Colo. — A new breathing apparatus could replace traditional SCBA and go a long way toward eliminating many firefighting heat-related ailments in the near future.

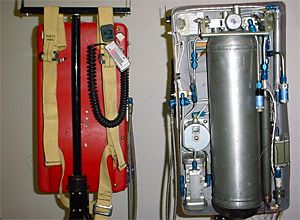

The SuperCritical Air Mobility Pack (SCAMP) system cools the wearer while also delivering the same amount of air as traditional SCBA, but in a smaller package.

Developers behind the technology are hoping to reduce the frequency with which firefighters are pulled out of service and cooled with water and ice packs.

"This system would never let a firefighter's core temperature get high enough for them to get heat stress, circumventing the problem right at the source," Colorado State University Professor Thomas Bradley, an engineer behind the project, said.

Research into more compact firefighter breathing apparatus was spurred as Kennedy Space Center found a need for firefighting equipment that could fit into space shuttle hatch doors approximately 20 inches in width and height.

SCAMP uses cryogenic technology to cool air to temperatures around minus 170 F, making it no longer a gas and not quite a liquid. Under the cryogenic conditions, the air takes up less space and allows the device to be worn as a thin backpack as part of a suit or specially modified turnout gear.

But what sets this technology apart from other breathing apparatus is its ability to cool the firefighter wearing it, Bradley said.

"The suit has water that flows throughout to transfer the heat from the firefighter's body to the pack, which acts like a heat sink," Bradley explained.

Though current prototypes resemble astronaut suits or thermal underwear, firefighters would also have the option to install the system into turnout gear as a special liner.

Since the project is scheduled for two years, the research could soon impact the fire service.

"The great thing about this project is that it can affect the safety of firefighters in the near term," Bradley said of the project, in contrast to some that can take upwards of 40 years.

The prototypes have also been designed with firefighter safety in mind.

"The plan is to get NIOSH testing done over spring and summer, then work on user interfaces and heads-up display since there are different diagnostics needed compared to the standard SCBA pressure gauge," Bradley said.

Poudre Fire Authority firefighters from the Fort Collins area will help with field testing of the breathing apparatus and help review designs.

"We support this research as improvements in the technology of protective systems will result in improved safety for firefighters," John Mulligan, Chief of the Poudre Fire Authority, said in a CSU press release. "This is promising technology that addresses the personal protection concerns of the modern firefighter."

Bradley, along with fellow CSU engineering professors Wade Troxell and John Williams, received a U.S. Department of Homeland Security grant of $917,000 for the project last month.

The team is working with Northern Colorado company Niwot Technologies on development of prototypes.

"Ultimately, the goal is for all firefighters to someday use this technology," Bradley said.

Copyright © 2024 FireGrantsHelp.com. All rights reserved.